By Andy Lagzdins

Electric motorcycles are on the verge of breaking out of their stigma of being inferior to gas bikes. After years of looking like science projects and bicycles with car batteries, Emotos have refined their looks and are appealing to more and more riders. Making electric bikes look cool is one thing, but making them competitive on the race track is whole different story. Looking at the electric bikes that are for sale right now, the KTM Freeride EXC is currently (in 2021) the best machine available from the big manufacturers to use as a platform for a racebike. It is a solid, reliable design that can be modified to compete in various disciplines. Parts are readily available from KTM through dealers that are signed up for the Freeride Program. It has been in production since 2015, but until recently has only come to the US in small batches. KTM had a working prototype of this bike back in 2008, when the goal was to build a zero emissions bike that was comparable with a 125cc two stroke MX bike. Eventually the Freeride ended up in a class of its own, somewhere in between a trials bike and an enduro bike. The forks, shock, hubs, and brakes are right off of the KTM85SX, and with the motor putting out basically the same power as a KX100, it makes sense to set it up as a Supermini. More specifically, with a 235lb weight, it is best suited as a mid-size bike for bigger kids 12-16 years old. This is not a direct stepping stone from KTM’s SX-E 5, but it does create an option for young riders to stay on electrics.

So with my platform and basic vision nailed down, I started the process of making the Freeride competitive with current Supermini’s. With the help of accomplished teenage racer Rocco Morse, we put together a bike that could run with some of the fastest Supermini offroad racers out there. This is a quick rundown of how we set up the bike that Rocco raced in 2021.

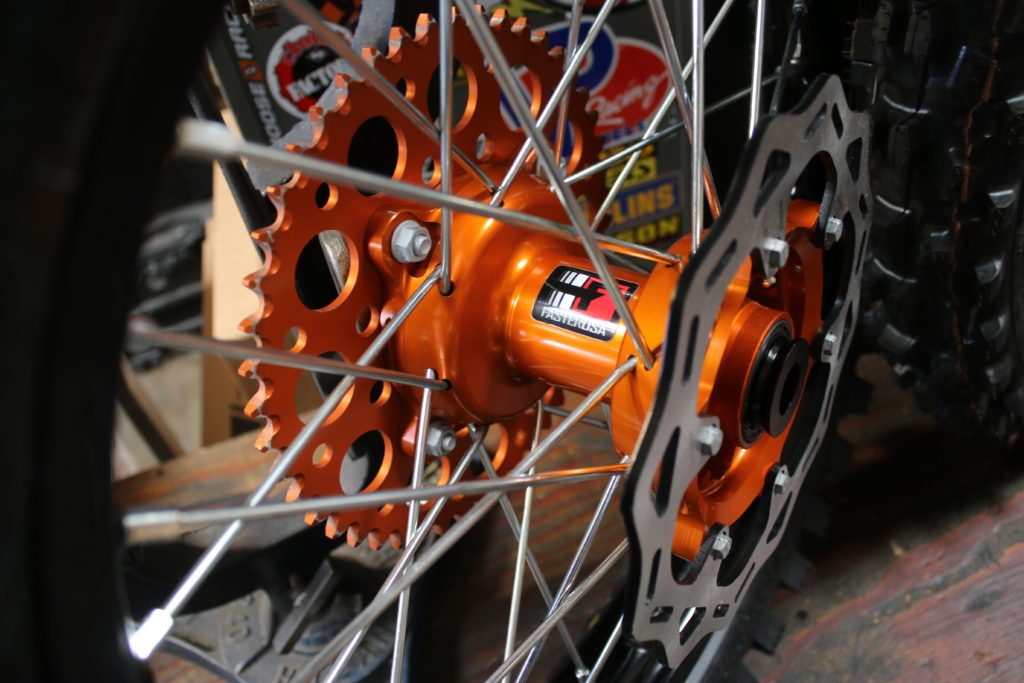

WHEELS

The first order of business was to change the stock 21/18 wheels to a set of 19/16 wheels to make it “legal” to run in Supermini classes. Most race series and events that offer a Supermini class have it in their basic requirements that the wheels have to be 19/16. The front and rear hubs on the Freeride are identical to KTM85SX hubs. I had Faster USA build a set of wheels with their 85SX hubs and Excel rims. The rims are 19”x1.60 front and 16”x1.85 rear. The tires we use are Dunlop MX33’s with OEM rim locks and Michelin AirStop HD tubes.

If you want to continue using the kickstand after installing the smaller wheels, the kickstand will need to be shortened about an inch. I like the convenience of the kickstand when moving and storing the bike. The kickstand unbolts easily with just one T45 bolt, and I take it off the bike before we go to the start line or before practice.

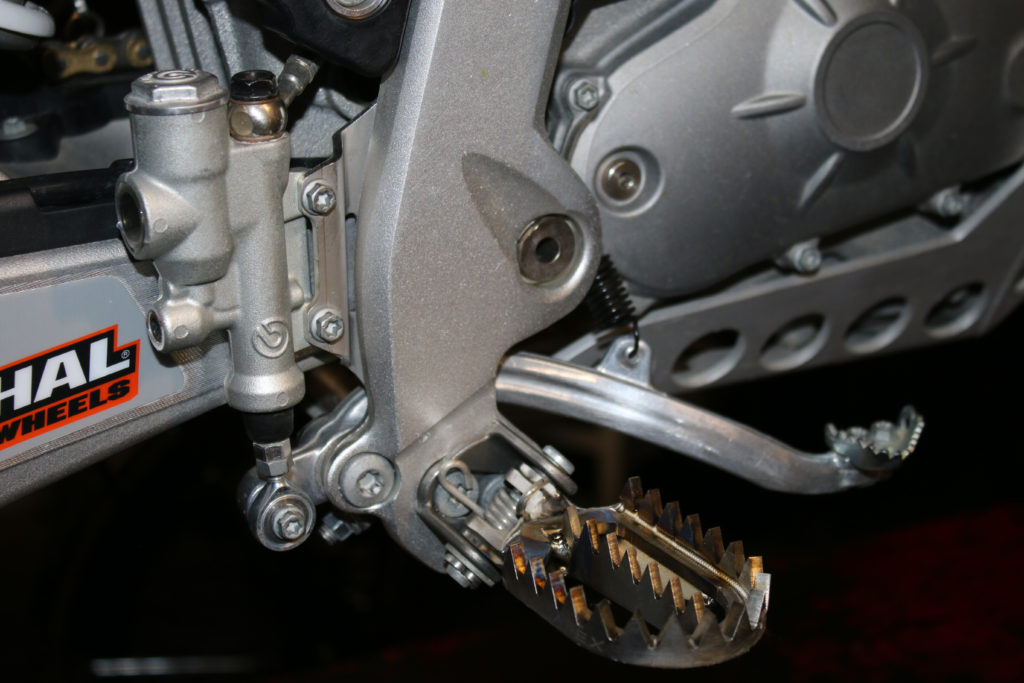

REAR BRAKES

The Freeride comes with a unique rear brake setup, in that it uses a caliper that is actuated by a hand operated master cylinder on the left side of the bars where your clutch lever usually goes. Changing the setup to a more “standard” foot pedal actuated rear brake is easy and straight-forward. Some riders like it on the bars and some riders like it on the pedal, but it really comes down to rider preference. I think that if the person riding the bike will ONLY be riding the Freeride, then the hand rear brake might be the best choice. If the rider will also be riding bikes with a foot brake, then from my experience its best to set up all the bikes that person will ride the same to eliminate the transition time from bike to bike. The foot brake system on Rocco’s bike is an OEM pedal and master cylinder mount from the 250R Freeride, and the master cylinder, caliper, disc and brake line from a 2020 KTM SXF.

The foot brake system on Rocco’s bike uses an OEM pedal and master cylinder mount from the 250R Freeride, and the master cylinder, caliper, disc and brake line from a 2020 KTM SXF. The SXF caliper will only fit onto a 2021 and later Freeride caliper mount.

With the 2021 model, the rear hub changed from a four bolt disc to a six-bolt disc. The diameter of the rear disc also went to 220mm. There is no OEM KTM rear brake disc available that is 220mm with a four bolt pattern. If you need to run the older wheel, Nihilo Concepts offers a disc to make it work.

2021 and newer wheel with 6 bolt disc.

2020 and older wheel with 4 bolt disc.

FRONT BRAKES

The front brakes on 2021 and newer Freeride EXC’s are pretty good, but there are easy bolt-on upgrades that bring the performance up to the level necessary for racing. KTM made it easy by making the caliper mount the same as current SX/SXF models. The complete front brake system from a 250 or 450 will bolt right on, and you can utilize the stock 240mm front brake disc. On Rocco’s race bike I use the caliper, master cylinder, and brake line from a 2020 KTM 250SXF.

The 240mm stock front disc is good, but a 260mm Galfer floating disc is better. The oversized disc is a KTM Powerparts item, and Braking makes a billet caliper mount bracket that moves the caliper out 10mm. The Galfer disc has the hole in it for the wheel sensor magnet, so the computer will still work. The larger 260mm disc comes in handy when slowing down the 235lb motorcycle. The floating aspect of the disc allows it to center itself between the pads after braking, which means less rolling resistance and heat.

The front brake master cylinder and brake line from the 2020 250SXF is a direct bolt-on. The stock Freeride handlebars don’t have much straight area where the master cylinder mounts on, so you might want to change to a different set of bars. Rocco prefers the Renthal 827 bend, which has more room for adjustment.

FORKS

The 43mm WP XPlor forks on the KTM Freeride are pretty good. They are set up on the plush side, and if you try to ride it hard or jump it, you will run out of adjustments pretty quick. On Rocco’s race bike I run WP 43mm XACT forks straight off a 2021 KTM85SX. A major benefit of using these forks is that I can effectively change the “spring” by changing the air pressure. It is great for when I have other riders testing out the bike and I can easily set it up for their weight by changing the air pressure. We have been running between 105-110psi, and Rocco weighs 130lbs with no gear. The added bonus is that these forks weigh less than the XPlor forks. David at Schmidt Performance revalved the forks, and other than that no parts were changed or upgraded. We use a Works Connection Holeshot device.

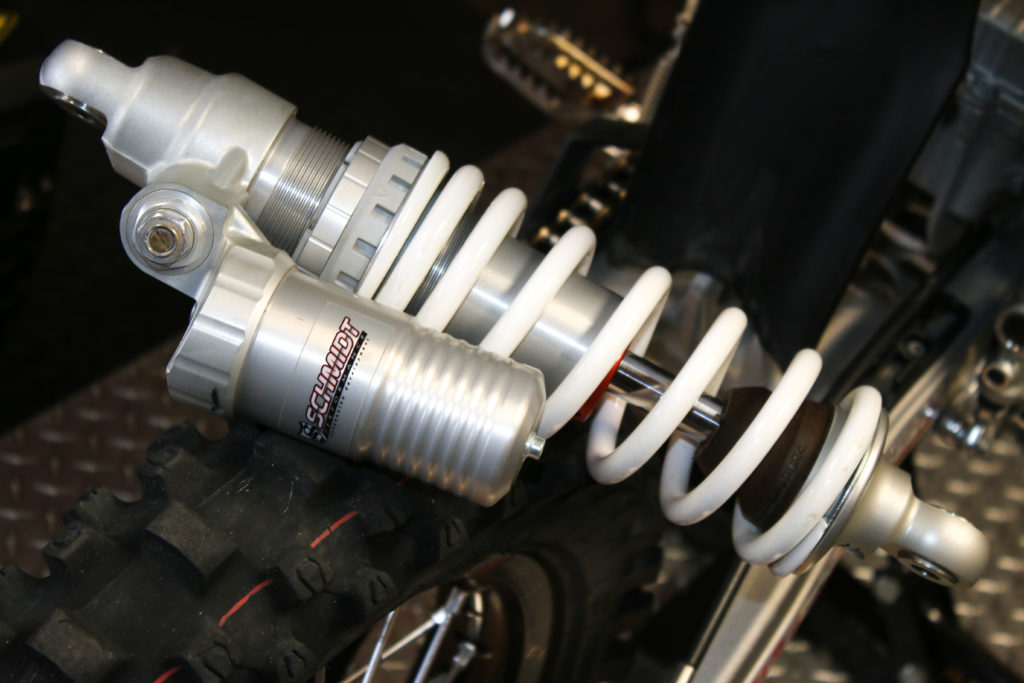

REAR SHOCK

The KTM Freeride rear shock is very similar to that of the 85SX, with the most notable difference being the overall length. The Freeride shock is one inch shorter than the 85SX shock. The Freeride shock is fully adjustable, with rebound and high/low speed compression adjustment. The shock on Rocco’s bike was revalved by David at Schmidt Performance.

As the bike comes, the compression adjuster on the rear shock is not easily accessible without pulling the subframe off. I made a hole in the battery box so I can get to the adjuster with a T-handle wrench. The seat flips up, and the 12v battery is removed without using any tools. The battery dangles nicely out of the way while making shock adjustments.

SPROCKETS

The KTM Freeride is geared for torque from the factory. The stock 11/48 gearing is ideal for actual “freeriding”, like wheelies, trials, urban obstacles and rock climbing. When I first installed the 19/16 wheels with the 11/48 gearing I did a speed check and it would max out at only 40mph. We went to a motocross track with that setup and it didn’t have enough top speed to clear any jumps. Over the next few rides on the bike, we went from 11/48 to 13/40. I kept going taller with the gearing, with no complaints from Rocco on the acceleration coming out of corners. The 13/40 gearing puts the top speed at right around 55mph.

A 13 tooth front sprocket is the largest that I feel comfortable mounting on the bike, because it puts the chain about 1/4” away from a boss on the crankcase. A 14 tooth front sprocket fits on and clears everything, but there’s not a lot of clearance, and a rock or some debris in the chain could spell disaster. The rear sprocket we are currently using is a 40 tooth aluminum by Sprocket Specialists. I prefer DID ERT3 non-oring chains and OEM chain guides and sliders.

SKIDPLATE

Many disciplines of off road racing combine high speeds and rocky terrain, necessitating extra protection for the motor case and other vulnerable areas of the bike. We made an aluminum skid plate that offers coverage on the sides of the motor. Since the skid plate also acts as a structural part of the frame, extra care had to be taken to ensure it would fit properly and not preload the frame. The stock skid plate and the bottom of the bike were scanned so all the dimensions were available for the CAD designer to create files for bending and cutting of the pieces. To have the best balance of strength and workability, 3/16″ thick 5052 aluminum was used. The finished product fits perfectly and offers substantially more protection than the stock skid plate. We have tested both solid and vented designs.

CONTROLS AND ERGOS

The user interface of the Freeride is quite minimalistic, mainly due to the absence of the clutch lever and shifter. The left side of the handlebars is completely bare, and the right side just has the throttle/switch assembly and the front brake master cylinder on it. My choice of handguards are Cycra ProBend with Moose mount brackets.

I installed a coolant temperature gauge in the bar pad. The gauge has a sensor in the coolant hose on the right side of the bike.

The key switch is relocated to behind the front number plate with a bracket attached to the instrument cluster mount.

Footpegs from 2015-era SXF’s fit right on, and I use Raptor Titanium pegs.

BODYWORK

The fenders and number plates on the bike are a mix of OEM Freeride and 85SX parts. The front fender, fork guards, and front number plate are all Acerbis 85SX. The radiator shrouds, battery covers, and rear fender are OEM Freeride EXC. The side number plates are OEM Freeride 250R. The seat cover is a pleated gripper by Red Label and the graphics are custom Team DirtFirst/Hollywood Movie Bikes. The OEM taillight and plate bracket are easily unbolted to clean up the back of the bike.

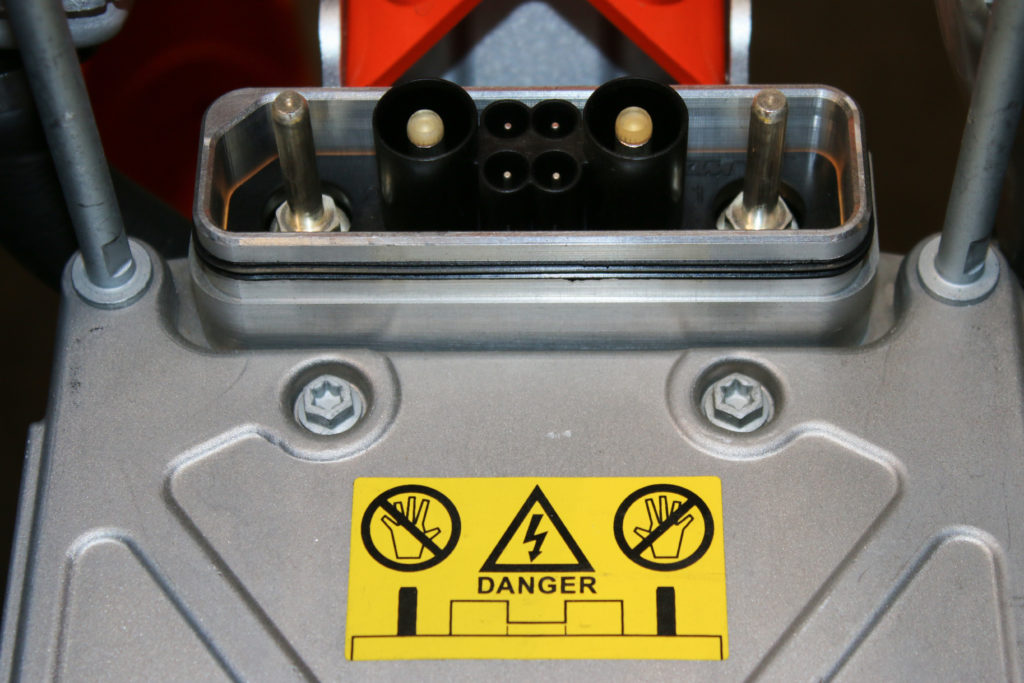

BATTERIES

With Rocco riding, we run the Freeride in Mode 3 all the time, unless we need to pace the battery consumption to finish a long distance race. For motocross races, running out of charge is not an issue. At desert race events the Youth loops are between 5-12 miles, and battery consumption varies depending on the terrain. It helps to be able to prerun the course to gauge battery consumption, so we can plan our pits. Our battery swaps average about 45 seconds, and only require one tool, an impact with a 10mm socket. I keep the studs for the battery mounts clean, with a thin film of grease on them. I also keep the o-ring on the electrical connector lubed so the battery slides in easily. I wait until the day before an event to charge the batteries, and transport them in secure Pelican cases.

The Freeride battery can go for up to 30 miles depending on the terrain, speed, and rider ability. KTM did a major update in 2018, when the range was extended by 50%. As the popularity of electric bikes increases, so will the amount of battery R&D by the manufacturers. There has been talk by KTM, Honda, Yamaha and others to use a standard battery made by Panasonic for their future electric bikes.

RACE PREP AND MAINTENANCE

This is one area in which the Freeride shines over its gas-powered counterparts. There is basically no maintenance work that needs to be done to the motor or controller, other than checking the coolant and oil levels. No piston, valves, clutch, crank, or transmission. There are a few bearings and gears in the transfer case, but the 200ml of gear oil stays clean for a very long time due to no clutch plate wear and resulting contamination of the oil. I kept checking the transfer case oil through six months of riding and racing (probably 50 battery cycles) and it never got discolored, so I changed it just to do it. This means one quart of oil will do three to four years of oil changes for an average rider.

The water pump is a separate sealed unit that fits into a hole in the side of the motor casting. It is literally held in place by the radiator hoses, and is easy to access and remove. When I say easy, I mean all you need is a screwdriver and some coolant to change your water pump. I run Engine Ice coolant in my bikes. Even though the highest coolant temperature I have measured is 130F, the controller can go into a limp mode from too much heat right around that range. The Freeride gets nowhere near the 200F+ temperatures of gas bikes, but it goes into a reduced power mode at a much lower temperature. That being said, if you are riding your Freeride in extended wide-open situations, keep your radiators clean, flush your coolant at least once a year, and remove your horn for more air flow.

So without the need for top-end rebuilds, valve adjustments, clutch replacements, air filter cleaning, carb rejetting, or silencer repacking, you can spend more time on maintaining the suspension, brakes, wheels, tires, and sprockets. The Freeride also has no rear shock linkage to service.

SPECIFICATIONS

Rider: Rocco Morse

Mechanic: Andy Lagzdins

Sponsors: DirtFirst Racing, Hollywood Movie Bikes, FasterUSA, Red Label MX, Schmidt Performance, 3Bros Racing, Galfer, O’Neal, Sprocket Specialists, NCY Motorsports, Parts Unlimited

Motor: Liquid cooled Permanent magnet synchronous

Max Power: 24.5hp @5000rpm

Battery: Lithium-ion KTM PowerPack, 3.9kwh

Rated Voltage: 260v

Transmission: Single-speed automatic

Front forks: XACT 43mm WP Air, revalved

Rear shock: WP Xplor PDS, revalved

Front travel: 278mm (11in)

Rear travel: 260mm (10.25in)

Frame: KTM steel-aluminum composite

Handlebars: Renthal 827 FatBar

Brakes: Brembo SXF calipers/master cylinders

Front rotor: Galfer 260mm

Rear rotor: Galfer 220mm

Chain: DID 520 ERT3

Front Sprocket: 13T Renthal

Rear Sprocket: 40T Sprocket Specialists Titan Tough

Grips: ODI

Skidplate: DirtFirst Racing

Seat cover: Red Label MX

Hubs: Faster USA billet

Rims: Excel Takasago 19/16

Tires: Dunlop MX33

Hand guards: Cycra Probend w/ Moose mounts

Foot pegs: Raptor Titanium

Holeshot device: Works Connection